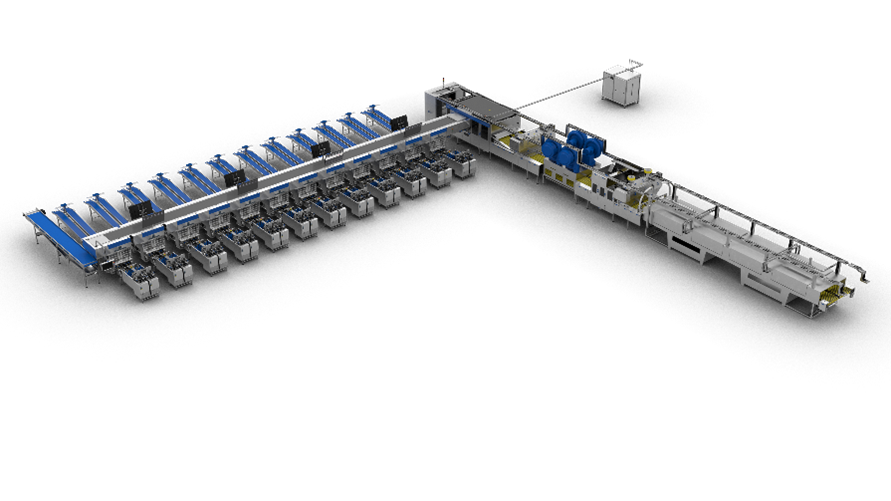

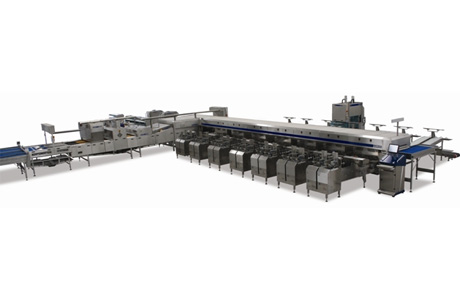

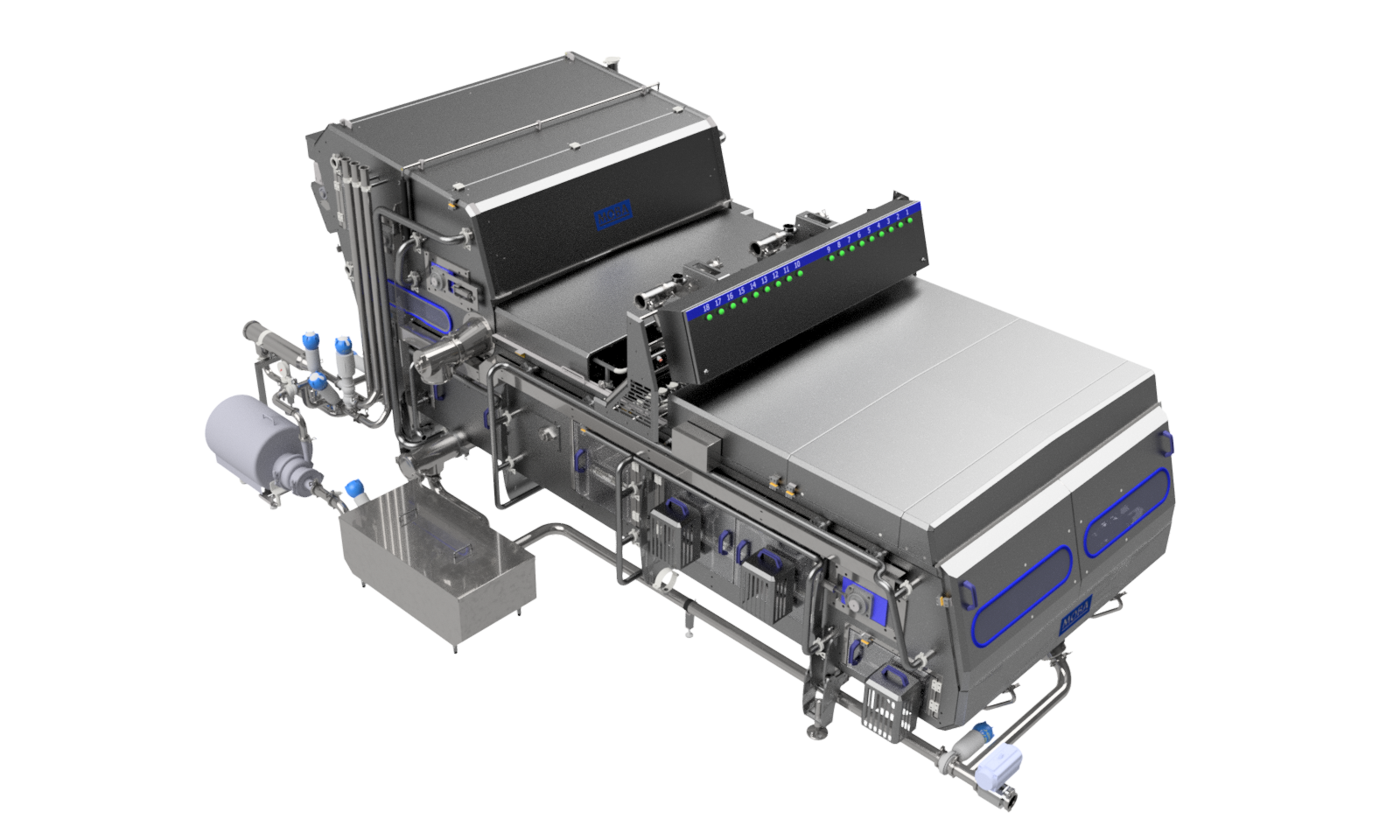

Case Packer MR12

The Case Packer MR12 is a Twin Case Packer robotic system especially designed for the high demanding market in the egg industry.

Product Information

A special and unique feature of the MR12 Twin Case Packer is the ability to process two independent products. Both channels of the MR12 can operate independently what makes this system very flexible. By using both channels on different grades, a very high and constant throughput in relation to floor space can be reached.

The MR12 can be equipped with following functions:

Extended gravity conveyor for manual input of empty cases

Connection to a compact case erector

Open pack reject conveyor for inline configuration

Straight forward case alignment unit

Smart cross-over for consumer packs and trays to connect to Contiflow Pack splitter

Specifications

Swipe this table side to side to view all specifications

| Technical Data | MR12 Case Packer |

|---|---|

| Function | Packs consumer packs and filled trays into cases and crates |

| Capacity indication (eggs/hour) | Up to 64,800 |

| Capacity indication (cases/hour) | 180 |

| Pack types | Suitable for processing consumer packs and trays |

| Footprint indicaton (L x W) | 3110 x 1100 mm |

| Power supply | Suitable for all 3 phase + neutral systems, both 200-230V or 380-420V, 50 or 60Hz |

| Power consumption | 10 KVA |

| Air supply | 6 bar |

| Air consumption | 13 m3/hour (designed as free air with pressure of 1 bar) |

| Dewpoint | 3 C° |

Downloads

Videos

Building Your Sustainable Egg Future

Find the Egg Handling System That Fits Your Operation

We provide customers with complete egg grading, packing, processing and handling solutions. We will help you by choosing the right system for the required egg grading job.

Related solutions