Contiflow

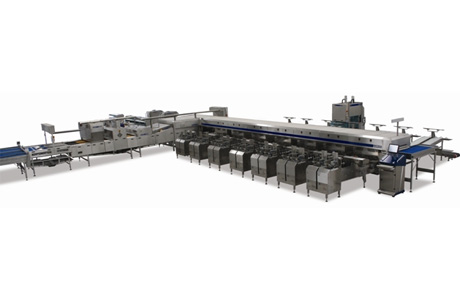

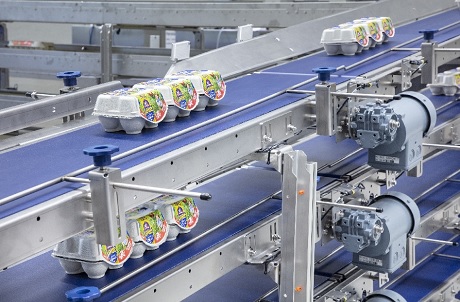

To transfer packs and trays from your egg grader to additional automation equipment, such as case packers and shrink wrappers. Moba Contiflow offers a fully flexible pack and tray transport system that helps to optimize your system layout, since it can be adapted to your building.

Product Information

The system is fully automatic, meaning human handling is reduced to a minimum. Adding Contiflow to your operation allows you to stack four conveyor levels with a manual pickup point on top. Without the manual pickup point, a maximum of five conveyor levels can be reached.

Moba’s Contiflow system offers optimum flexibility and can merge, transport, sort and buffer a range of consumer packs, as well as pulp trays. Open packs can also be rejected on Contiflow. With the Contiflow system, you can transfer up to 65,000 eggs/hour per level, depending on the pack size.

Contiflow can play a crucial role in your operation, especially if you want to connect case packers offline. How does it exactly work? The grader packing lane feeds the packs onto the Contiflow shooting lanes. The grader packing lanes are connected to one of the Contiflow levels, or the manual pickup point, for maximum flexibility. Each Contiflow level is connected to one case packer.

The Contiflow system comprises two main sections: a base section and a delivery section. The Contiflow base section transports the packs from the grader to the merge conveyor, while the delivery section transports the packs from the base section to one or more packing machines.

Double product mode

Contiflow features a double product mode which makes it possible to run different packs on one transport level at the same time. This optimizes the packing capacity for smaller batches running in parallel. This feature is designed for egg producers with an MR12, since this robotic system can process two independent products.

Check your operation in 3D

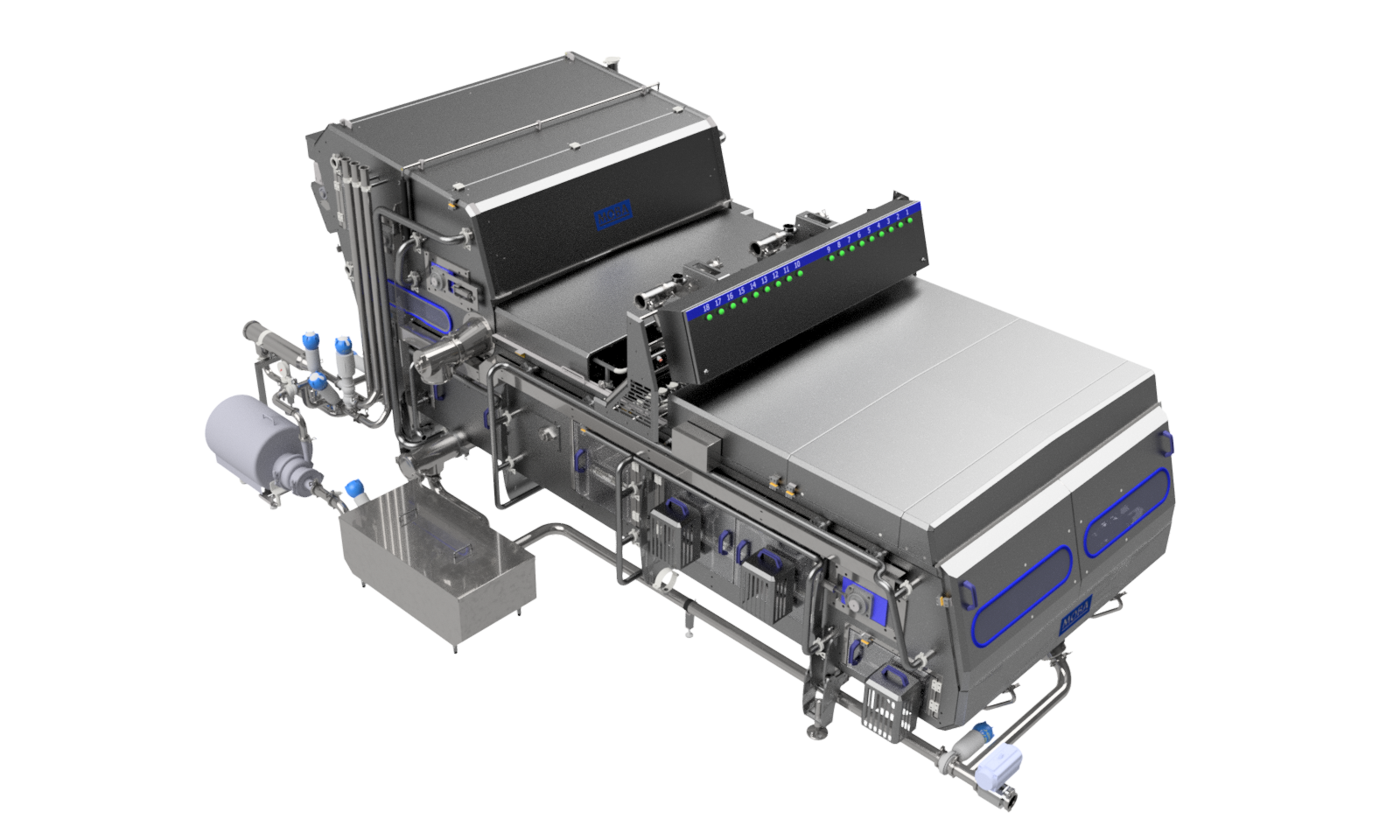

A huge advantage of Moba’s Contiflow system is that it offers a dynamic 3D visualization of the entire process. The position of the packs, alarms and statuses displayed on the 3D viewer directly reflect the current situation. This means that in the event of a blockage, Contiflow provides the operator with a detailed view of the location, leading to improved uptime.

Specifications

Downloads

Videos

Related solutions