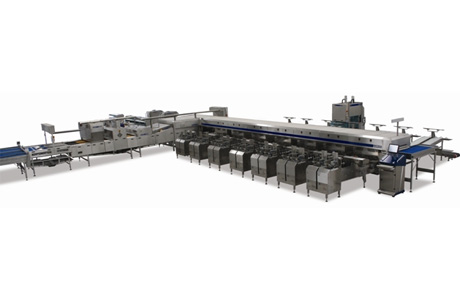

Building Your Sustainable Egg Future

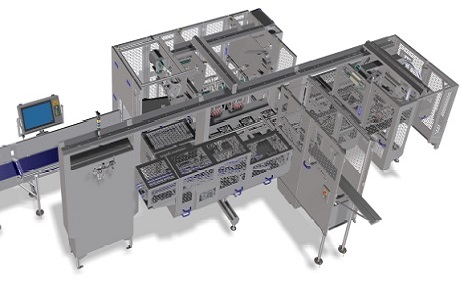

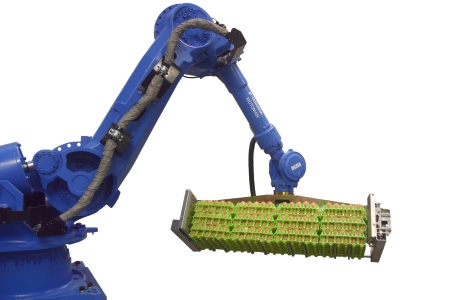

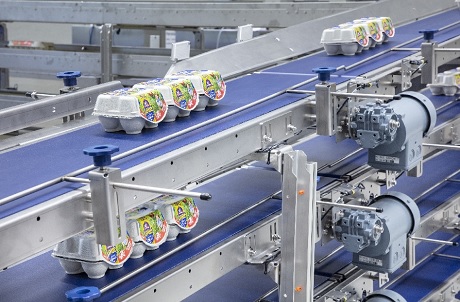

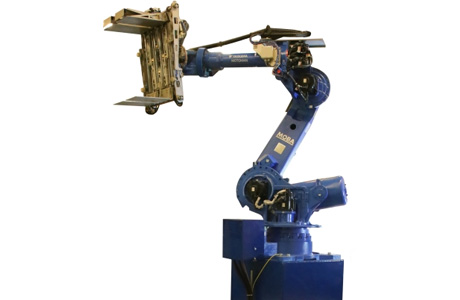

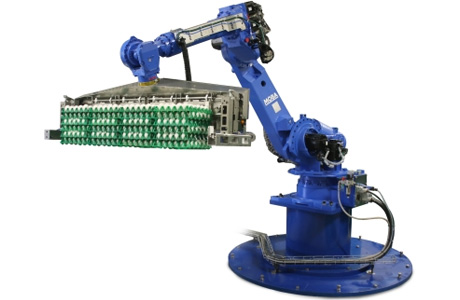

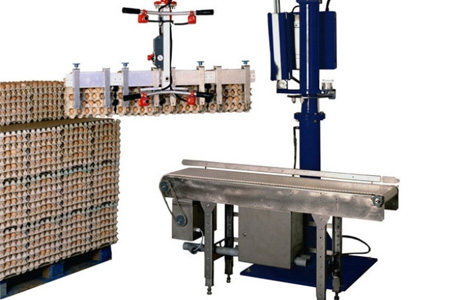

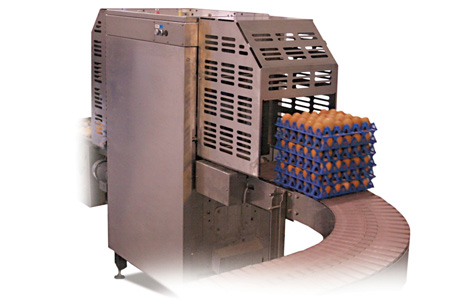

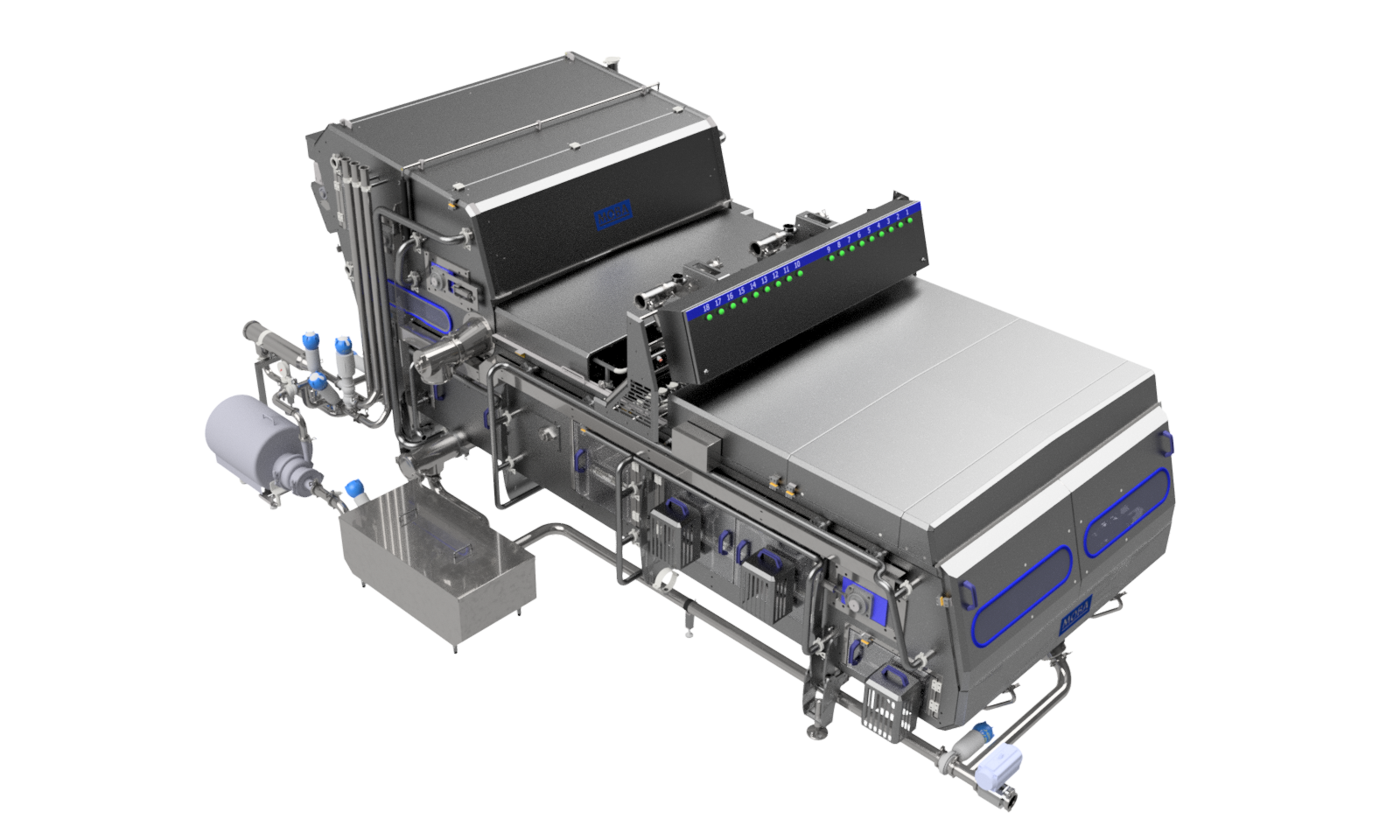

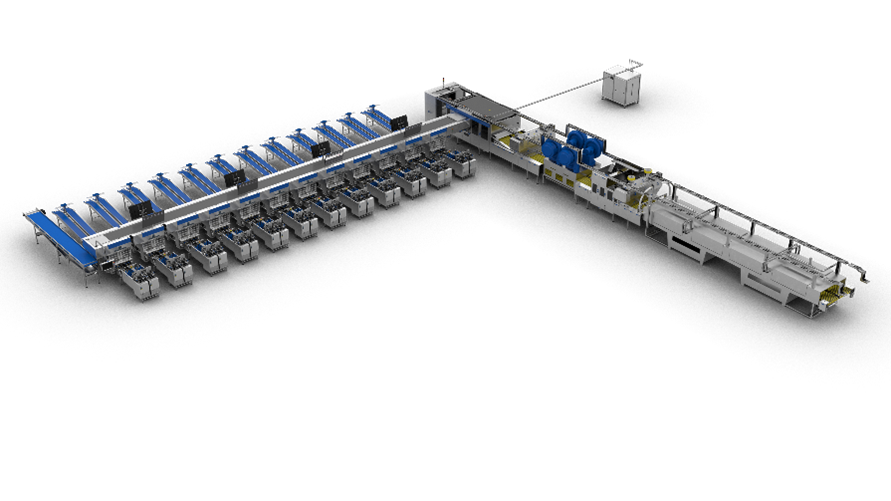

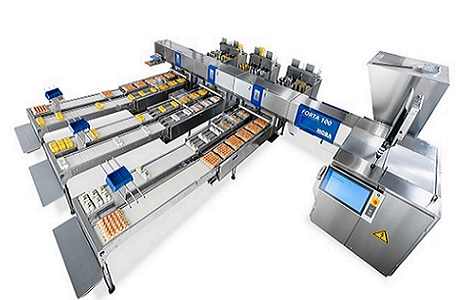

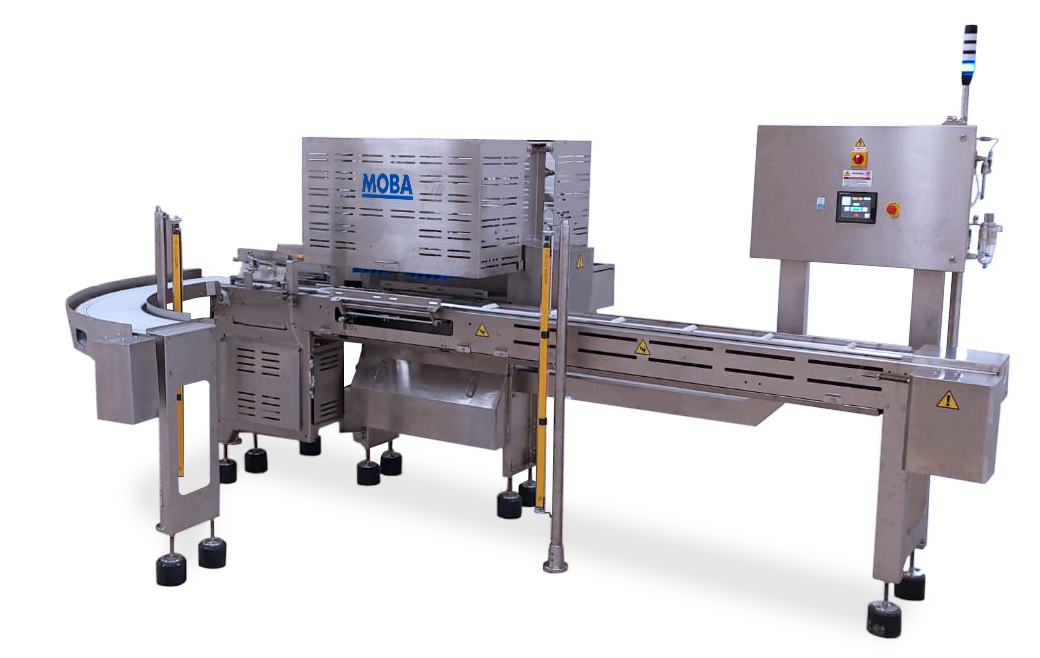

Automation to Enhance Your Performance

Solve labor challenges with Moba’s easy-to-use automation solutions. Enhance efficiency, increase production levels, and improve quality. Stay competitive and succeed in the evolving egg industry.