Ohmic

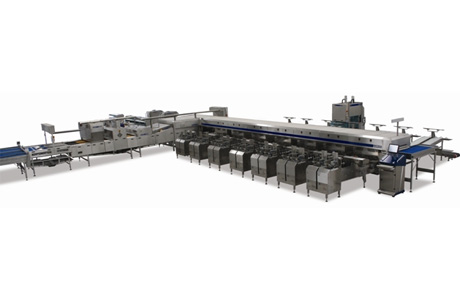

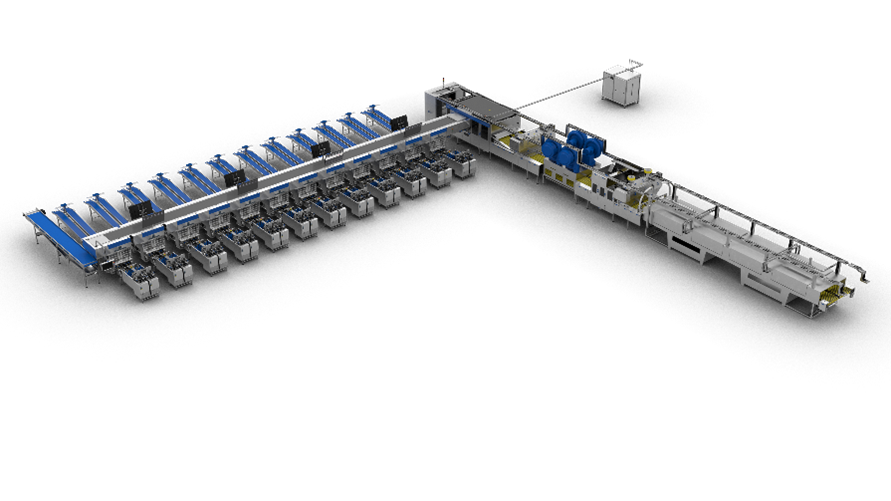

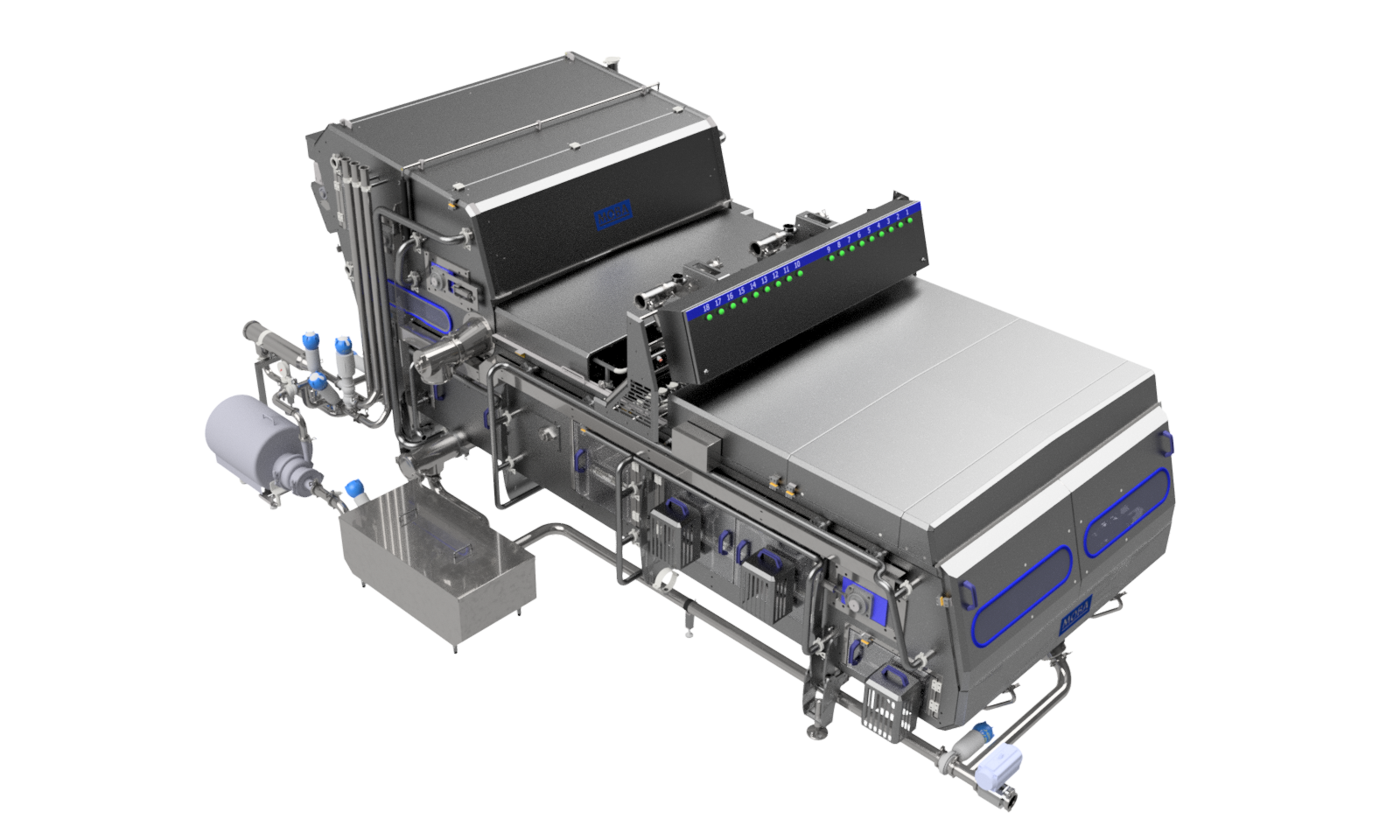

Moba Ohmic product heating is applied for final product heating prior to pasteurizing. The major benefits of this new method: Impressive cost savings due to extended run times(up to 50%). A better end-product with a longer shelf life.

Product Information

Specifications

Downloads

Videos

Building Your Sustainable Egg Future

Mauro Bertazzo, Ferraris S.r.l.

“Compared to traditional pasteurization, we’ve seen a remarkable 6-8% increase in viscosity and a complete elimination of clots. Our customers who produce snacks with chemical leavening have reduced their water dosage by 1.5%, making our product stand out from the competition. The product remains stable for over 4 weeks, with minimal pH variation. The new system has also proven to be effective against sporigenic bacteria.”