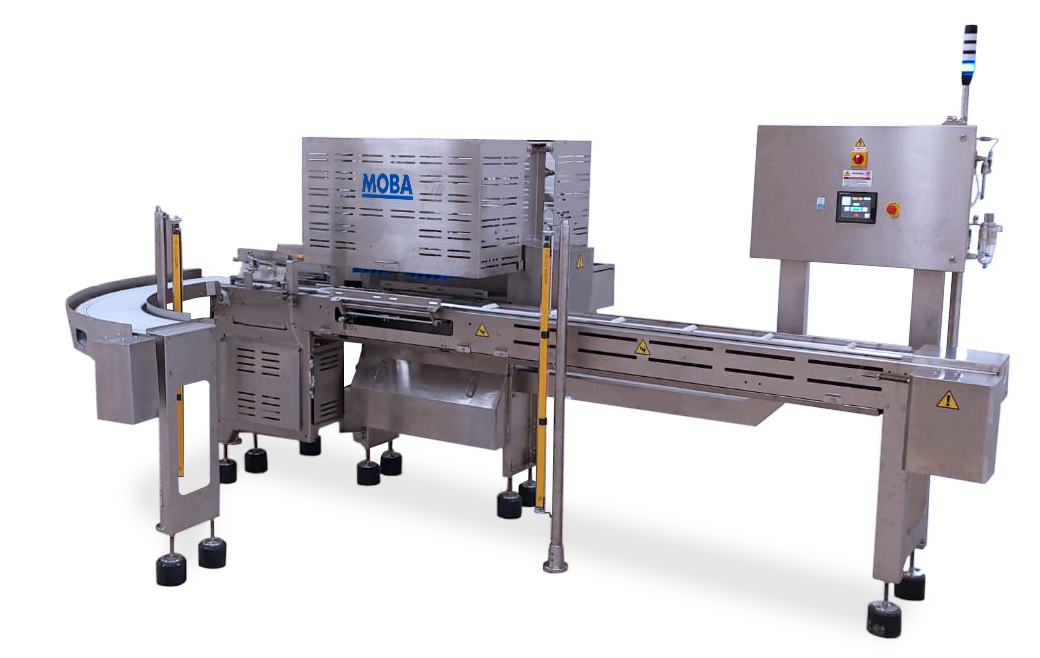

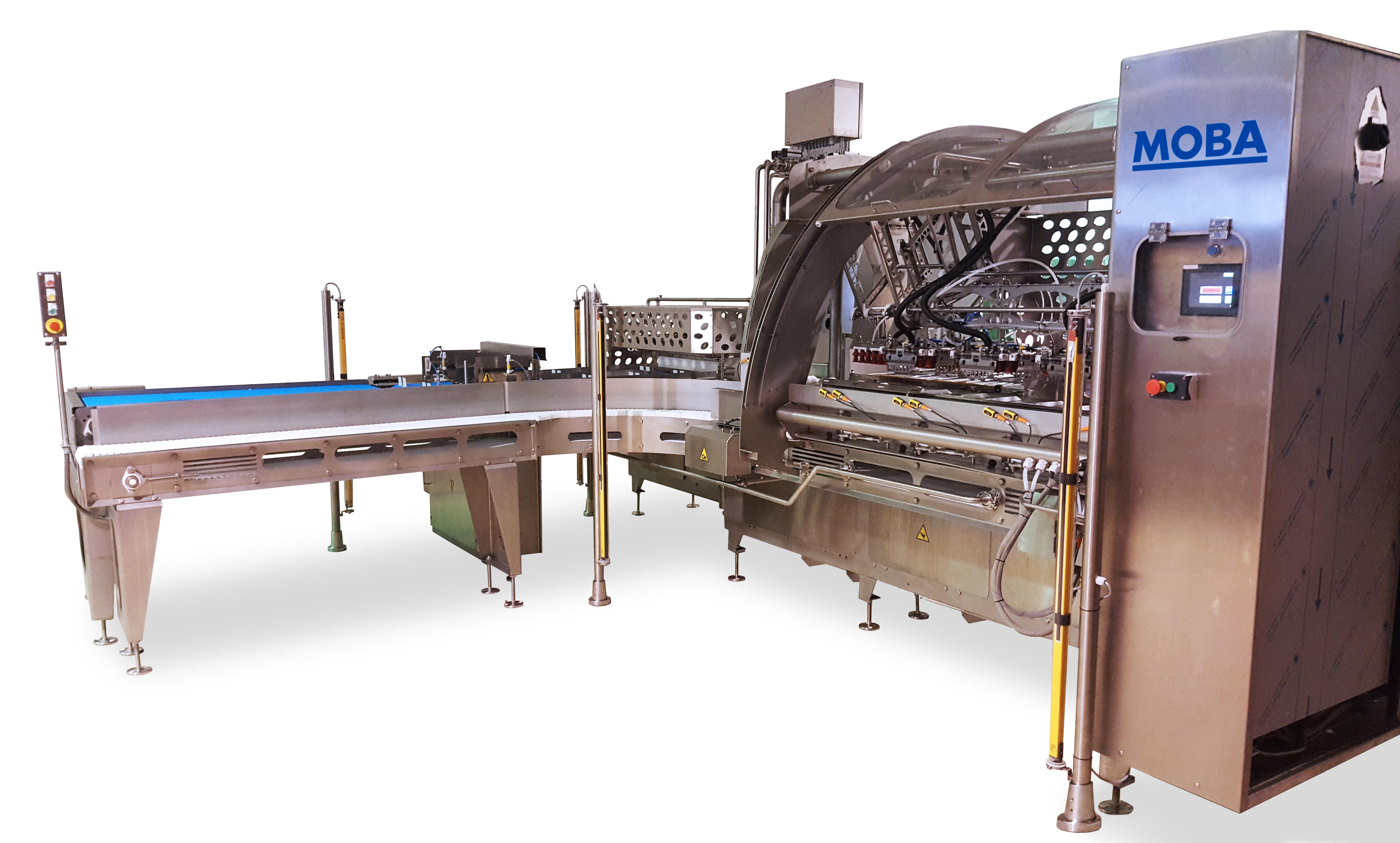

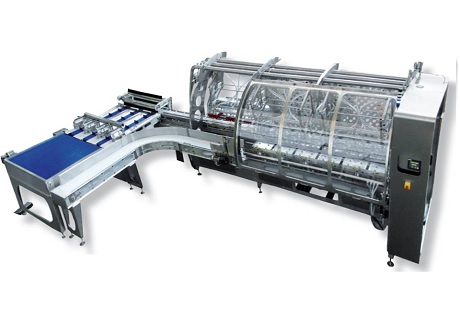

The Ovolution500 egg pasteurizing system is an all-in-one solution for liquid egg products. The equipment is easy to install and use. This fully automatic system incorporates a filtration system (manual or automatic) and a 500 l/h plates based pasteurizer with a product filling station.

In the Ovolution500, the filtered liquid raw egg is heated to pasteurizing temperature to eliminate bacteria and then immediately cooled down under four degrees Celsius. The equipment guarantees maximum performance and a lower risk of production or operator mistakes.

The main features are:

- The capacity of production:

– 500 l/h of basic egg products (whole egg, egg whites)

– 250 l/h (egg yolk) or simple egg blends - Compact system, skid-mounted (small and adaptable footprint)

- Low production costs and high energy recovery due to regeneration plate section (system recovers energy from the pasteurized product)

- High level of bacteria reduction

- High-quality egg products (nature egg products and blends)

- Easy installation

- Total stainless steel construction

- Best homogenizing technology that combines:

– Better quality of the product

– Extended pasteurizing/run times (fewer downtimes)

– Less energy consumption

– Less chemical usage