Increase Food Safety and Protect Your Image

Ensuring food-safe production is the foundation of your business. To support you, we innovate to meet the highest hygienic standards, comply with regulations, and minimize the risk of cross-contamination.

Ensuring food-safe production is the foundation of your business. To support you, we innovate to meet the highest hygienic standards, comply with regulations, and minimize the risk of cross-contamination.

Keeping your production environment food-safe is a daily challenge. It takes dedication and discipline to keep everything clean and avoid non-conformities—but it’s also what builds your reputation as a trusted supplier of quality eggs.

At Moba, we get it. These market demands have shaped how we design our solutions to support you in maintaining the highest hygiene standards. That’s why we focus on:

By following these principles, Moba has developed an industry-leading approach that includes:

At Moba, food safety isn’t just a requirement, it’s what drives us forward. We’re always pushing the limits with innovative solutions and technology to improve hygiene in egg production.

Customer Stories

Discover the impact we’ve made through our customers’ own words, showcasing the benefits and successes they’ve experienced.

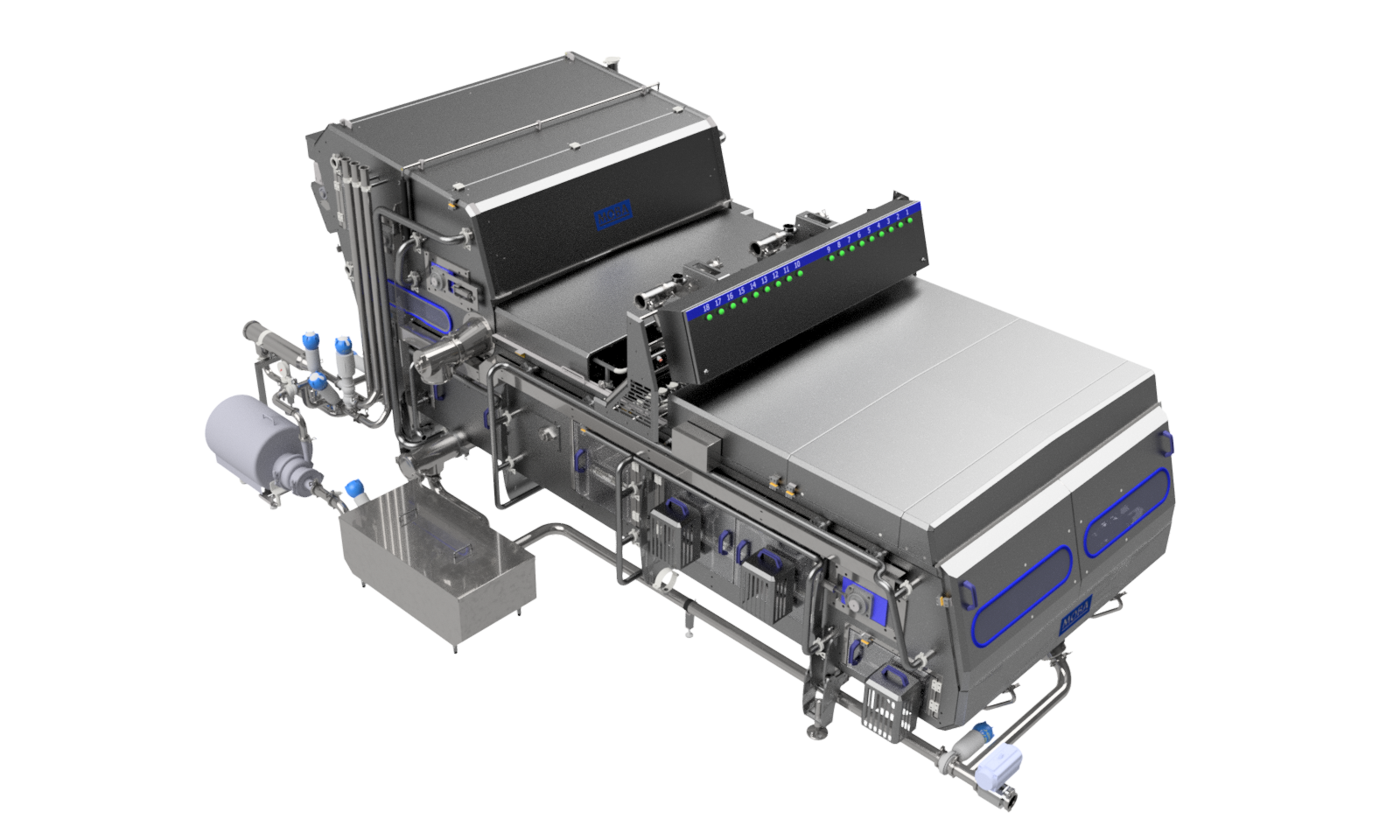

With the Omnia PX series, Moba sets a new standard within the industry regarding three important goals for egg producers.

Moba has developed a new way of detecting cracks in the eggshell and a vision based weighing system. By combining the possibilities of the latest technology in visual systems with artificial intelligence ("AI"), Moba has set a new standard in crack and weighing detection.

The Synchro626 is the biggest egg breaker separator in the world. It is a 15-row breaker with a maximum capacity of 225,360 eggs/hour (626 cases/hour).

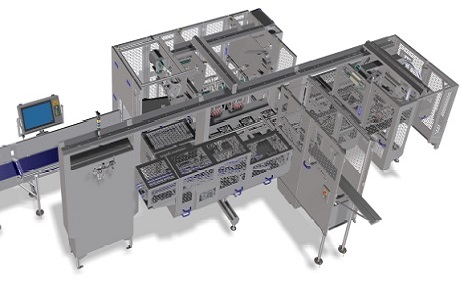

The Proxima breaker series sets a new standard in egg processing. Built on the trusted foundation of Synchro egg breaking machines, Proxima delivers higher yield, greater hygiene, and smarter operation, all in a compact design. With innovations like closed-loop CIP, recipe-based operation, and advanced detection, Proxima is engineered for processors who demand more: more efficiency, more reliability, and more future-readiness.

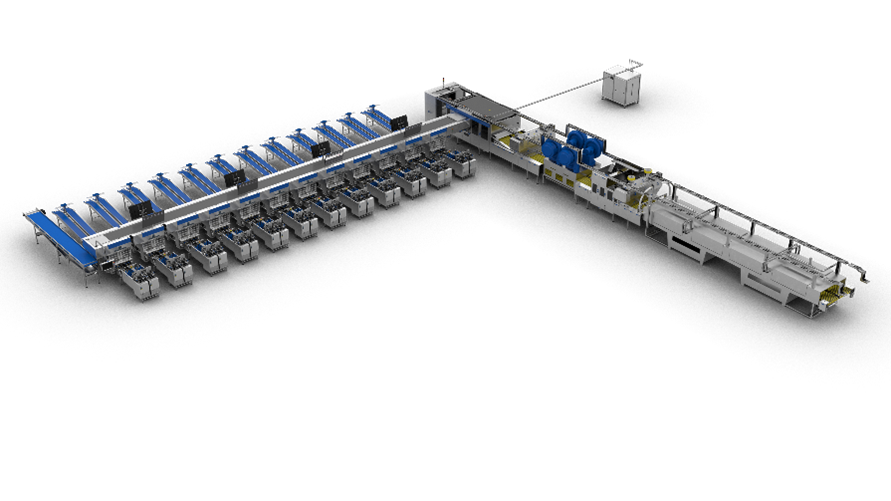

The Magna grading system is built to pave the way for a connected future. It combines real-world insights with smart innovations in production control for unmatched performance and reliability.

The ML loader is equipped with all features you may expect of a modern high capacity loader, with the highest standards of food safety in mind.

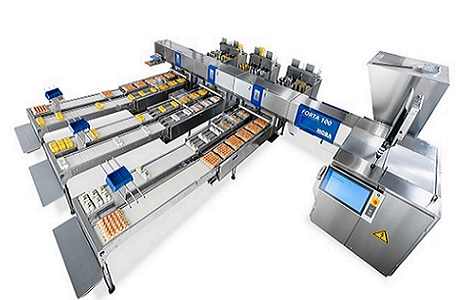

The Forta GT promises reliable topline technology, high hygienic standards and can be configured to your specific needs.

Moba Ohmic product heating is applied for final product heating prior to pasteurizing. The major benefits of this new method: Impressive cost savings due to extended run times(up to 50%). A better end-product with a longer shelf life.